Choose the Right Centrifugal Blower Fan for Your Needs

Welcome to ACCEL India, the leading centrifugal blower manufacturer in India

At ACCEL India, we understand that every customer has different needs and requirements. That’s why we offer a comprehensive range of centrifugal blower fan manufacturers in India, from small models that can move 400 m3/hr of air up to large ones that move 10,000,000 m3/hr. Whether you’re looking for a fan for industrial or commercial applications, we have the perfect product for you.

Heavy Duty Industrial Exhaust Fan Manufacturers in India

We also offer a wide selection of industrial exhaust fans and heavy duty industrial exhaust fans. Our products are designed to provide efficient air flow, reliable performance and long-lasting durability. We are known for our high quality and competitive prices, so you can rest assured that you are getting the best value for your money.

Wide Range of Industrial Fans and Blowers Manufactured in India

We offer a wide range of industrial fans and blowers manufactured in India. From commercial fans to heavy-duty industrial exhaust fans, we have something for every need. Our products are designed to provide optimal performance while being easy on your power bill. All of our products are backed by our reliable warranty and customer service.

Why Choose ACCEL India?

At ACCEL India, we strive to provide the best quality products at competitive prices. Our experienced team of engineers and technicians are dedicated to providing you with the best customer service and support. We are committed to providing you with the highest quality, so you can rest assured that you are getting the best product for your needs, and from the best centrifugal blower fan and industrial fans and blowers manufacturers in India.

Order Your Centrifugal Blower Fan Manufactured in India Today

If you are looking for the best centrifugal blower fan manufacturers in India, look no further than ACCEL India. We offer a wide range of high-performance products at competitive prices. Contact us today to learn more about our products and to order your centrifugal blower fan today!

Choose ACCEL India for Your Industrial Fans and Blowers Needs. So don’t wait – Discover your ideal fan or blower or Get your centrifugal blower fan now!

Contact us now to learn more about our products and to order your centrifugal blower fan today!

Get An Instant Quote…!

AIR CONTROL & CHEMICAL ENGINEERING CO. LTD.

An ISO 9001: 2015 certified Company

Features:

- Incorporates both the compressor and motor in a single housing, reducing footprint.

- Built on the rugged and proven industrial design of ACCEL SMC series compressors.

- Inbuilt motor winding protection with PTC thermistor for protection against motor overload.

- Operation upto 60° C condensing temperature to suit Indian and high ambient condition.

- Compatible withecofriendly Refrigerants like: R-134a, R-404a & R-407c.

- Easily repairable at site.

- EMI/EMC compliant as per MIL 461-E/F

Semi Hermetic HS Series Compressor for Air Conditioning and Refrigeration Applications

- Evaporating Temperature Range : (-) 35°C to (+) 10°C

- Condensing Temperature Range : 30° C to 60° C

- Operating Voltage : 380-460V / 50 Hz

Optional Features:

- Stepwise capacity control through Solenoid Valve.

- Stepless capacity control with VFD drive, speed will be regulated as per pressure or temperature requirements with inbuilt relays for pressure safety cutouts.

- Oil Separator with timer controlled oil return for low temperature applications.

- Set of tools and normal spares

- Pressure switches cutouts and gauges

- Crank case heater.

- IP 55 terminal box

Capacity Rating with R-22 gas,rating charts for other gases are available on request.

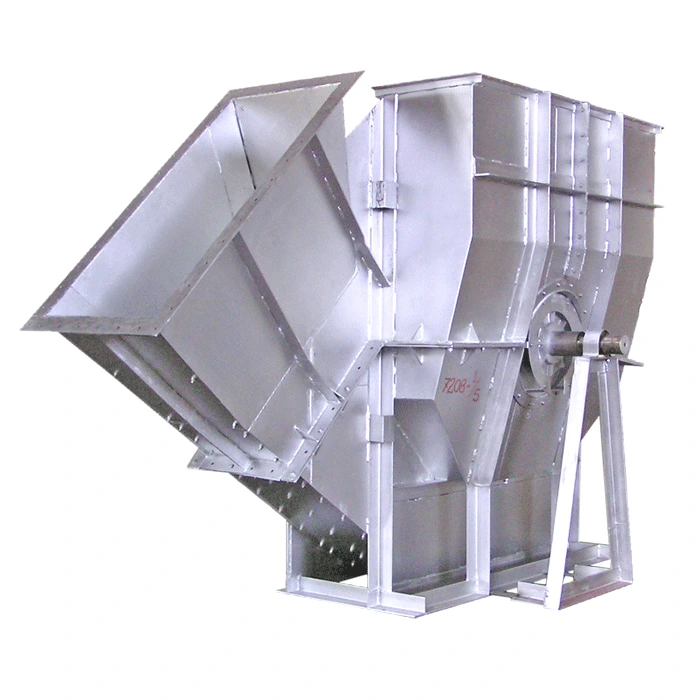

Industrial fans and blowers manufacturers in India

CCEL Centrifugal Fans & Blowers Cater to wide variety of light and heavy duty applications in wide spectrum of industrial sectors.

Range : | 400 m3/hr (Minimum) – 10,00,000 m3/hr (Maximum) |

Static Pressure : | 6mm of WG (Minimum) – 2000 mm of WG (Maximum) |

Size(Impeller Diameter) : | 275 mm (Minimum) – 3000 mm (Maximum) |

Models : | CSDA / CSSA / CRTA / B & F / PH / MX / MH / XB / XS / XE / XC XO / 86 / 96 |

Application : | ID Fan, FD Fan, Coal Mill Fan, ESP Fan, Cooler Fan, Air Slide |

| Blower, Cool Vent Fan, Nose Cooling Fan, Bag Filter Fan,Exhaust Fan, | |

| Supply Fan, Roof Ventilator, Bifurcator, Axial Flow Fan. | |

Benefit : | Wide Selection, High efficiency, Low sound level, Excellent for dust |

| loading applications, Economical, Use of Special alloys, Wider choice of | |

| flow control methods, Special design for hot gas applications, | |

| Rapid temperature swings. | |

Constructional Features : | Spark Proof / Spark Resistant Blade Liner (Replacement) – To resist wear & |

| tear of major parts. | |

| Impeller Hard Facing – Sweat on paste / Electrode / Wear Plate. | |

| Lining – Rubber / FRP / Ebonite / Neoprene (For Chemical Industries). | |

| Construction – MS / SS / Aluminium. | |

| M.O.C of impeller – Weldox / ASTM / Tiscroll (For High temp). | |

| Coating – Zinc Spray / Hot Dip Galvanizing / Epoxy. | |

| Noise Control – Rockwool Insulation / Silencer. | |

| Impeller Washing Arrangement – Water / Steam. | |

| Capacity Control – Inlet / Outlet / IGV / BDMP Damper. | |

| Sealing – Dry Plate / Gland packing / Labyrinth / Mechanical. | |

| Drive – V Belt / Coupling / V VV F / Gearbox / Fluid / Hydraulic Coupling. |